Motor Element Summary

Induction & Permanent Magnet Motor/Generators

Permanent Magnet (PM) and Induction motor elements come in identical pole configurations; 2, 4, 6 and 8-pole machines are available in both technologies.

Synchronous (PM) configurations offer higher efficiencies, higher tip speeds, larger rotor bores (stiffer shafts), lower rotor temperatures and increased power densities over induction machines.

Asynchronous (Induction) motor/generators are lower cost, have more robust rotors (can withstand higher temperatures) and are easier to handle than PM machines (simpler to balance, easier to assemble rotors into stators, no magnets to deal with).

e+a Permanent Magnet And Induction Motor/Generators Are Direct Drive Alternatives To Bulky And Expensive Geared Systems.

Contact us today with your application requirements!

Rotor & Motor Element Types

-

PM Rotors with Carbon Fiber Reinforced Plastic Sleeves

Tapered sleeves with large rotor bores allow rigid drive trains, the fastest tip speeds and use a simple, non-thermal scheme to secure the shaft to the rotor.

-

PM Rotors with Ferrous Alloy Sleeves

MEBA™ steel sleeves allow higher rotor temperatures, are very durable, create lower windage losses and can be used in cryogenic applications.

-

PM Rotors with Interior Magnets (IPM)

IPM machines have high torque, a wide field weakening range (ideal for machine tool applications) and do not require a sine filter between the VFD & motor. This makes them ideal for high-volume, cost or weight sensitive OEM applications requiring a PM motor/generator but eliminating the expense and bulk of a sine filter.

-

Torque Motors

Low speed, very high torque motors with high pole counts. e+a torque motors come with a metallic sleeve to improve their durability and reliability. This ensures that even under unfavorable conditions the magnets are protected from mechanical damage and remain solidly attached to the rotor.

-

Core Magnet PM Rotor with Metallic Sleeve

2-pole, high speed applications like Fuel Cell Compressors benefit from this design; a shaft is integral to the basic configuration.

-

2, 4, 6 & 8-Pole Asynchronous (Induction) Motors

Induction motors are simple in construction, rugged and have the ability to handle high temperatures and difficult environments.

-

Aluminum Rotors

e+a induction motors with die-cast aluminum squirrel cage rotors are inexpensive, have a long service life and a low rotor weight (maximum tip speed of 130 m/s).

-

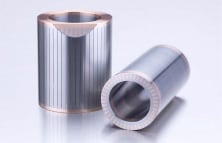

Copper Rotors

e+a Induction motors with copper rotors have a larger bore and tip speeds to 220 m/sec using a short circuit ring for reinforcement.

-

ASMpro with Copper Profile

ASMpro machines have a temperature resistant rotor, require no voltage protection, are simple to start up and control, have high torque and a broad speed range.

-

Special Design with Copper Rotors

e+a offers its series of high pole-count asynchronous machines with special copper rotors for applications requiring high torque and a wide speed range. They are characterized by high torques at low speeds for a simultaneously large field weakening range.

-

High Pole Count Examples (Induction Motors)

1,000 Nm @ 10,000 rpm: 8-pole, 30cm stator OD

3,000 Nm @ 6,500 rpm: 12-pole, 42cm stator OD