Permanent Magnet Motor/Generator Elements

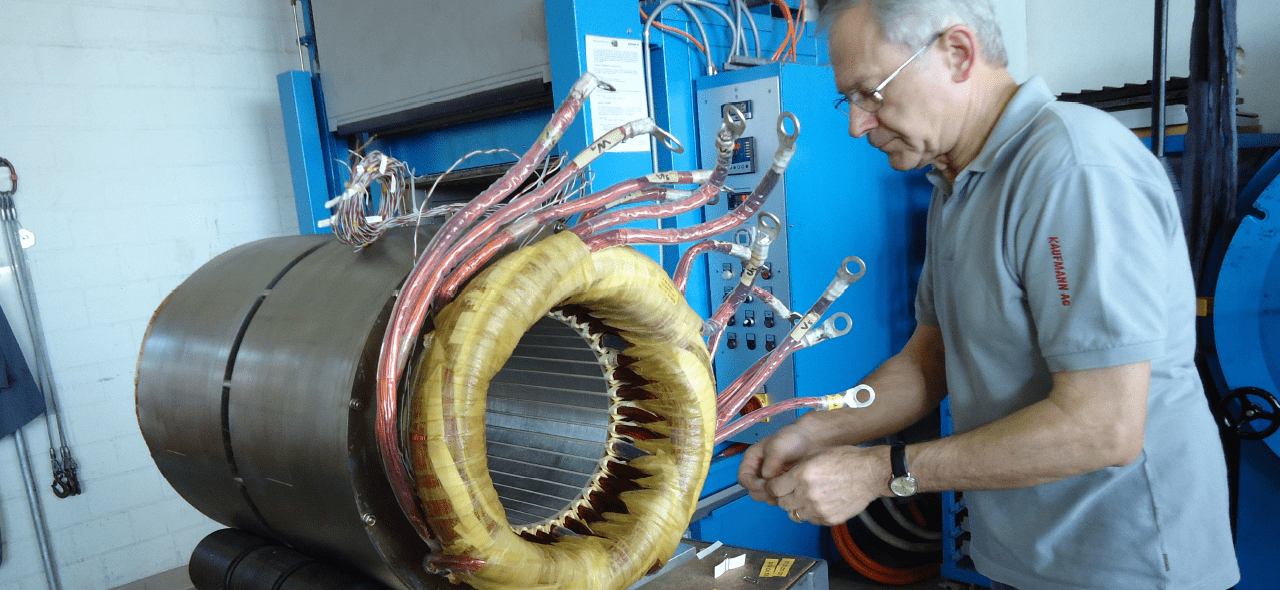

Permanent Magnet Rotors & Stators For High Performance Applications

Permanent Magnet Motors are the most common choice for turbomachinery applications. These motor/generators are high-efficiency, can support the fastest speeds and provide the highest power and energy densities compared to induction motors. Efficiency differences between PM and induction machines sometimes amount to only several percent, but this is enough for PM motors to be almost the exclusive choice for Generator applications.

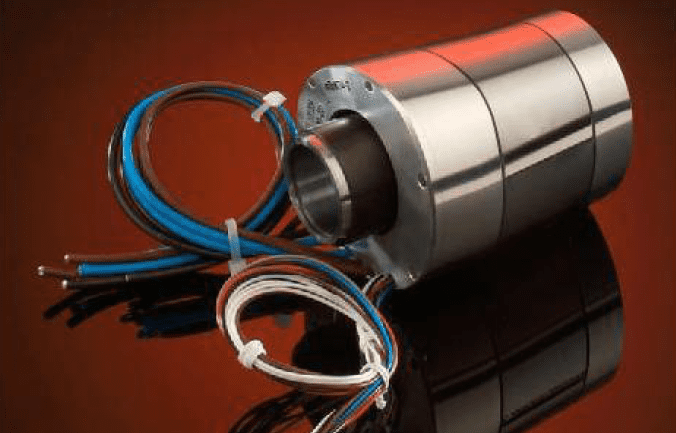

Permanent Magnet (PM) elements are available in the same pole configurations as induction rotors and stators. Synchronous (PM) configurations offer higher efficiencies, higher speeds, larger rotor bores, lower rotor temperatures and increased power densities over induction machines. Rotors can be installed quickly without prior thermal treatment of the rotor or shaft and PM rotors can be removed and reused.

Rotors are typically made of carbon fiber overwraps of steel cores populated with high-temp permanent magnets; optionally the overwraps can be MEBA™ metallic rotor sleeves.

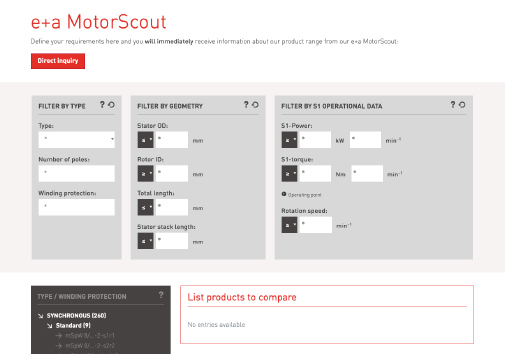

e+a MotorScout

-

MotorScout

MotorScout is e+a’s online database of commercial motor types for both Induction and PM synchronous Motor/Generators.

Input required motor characteristics and MotorScout will return a list of design possibilities that could work in your application, both Induction and PM. If MotorScout does not return any possibilities, e+a may still have designs for those requirements. Contact us directly.

Visit: https://motorscout.eunda.ch

Contact: mdrumm@eandausa.com and let an e+a engineer recommend a solution to fit your needs.